What is fiber optic cable made of? A fiber optic cable is a complex assembly made from specific materials tailored to effectively guide light for data transfer. With a core of glass or plastic encased by protective cladding and an outer layer, this article unravels what these materials are and how they contribute to the cable’s performance.

Key Takeaways

- The core of fiber optic cables is made of either glass (silicon dioxide) for long-distance transmission with minimal signal loss or plastic (polymer) for short-distance applications and flexibility.

- Fiber optic cables are encased in protective cladding material such as fluoride-doped silica to maintain total internal reflection and buffer tubes to protect from physical damage, with a final outer jacket layer for further abrasion and moisture resistance.

- There are two main types of fiber optic cables: single-mode, which allows for long-distance transmission with minimal signal attenuation, and multimode, which is capable of transmitting multiple light signals simultaneously for high data capacity over shorter distances.

Exploring the Core Elements of Fiber Optic Cables

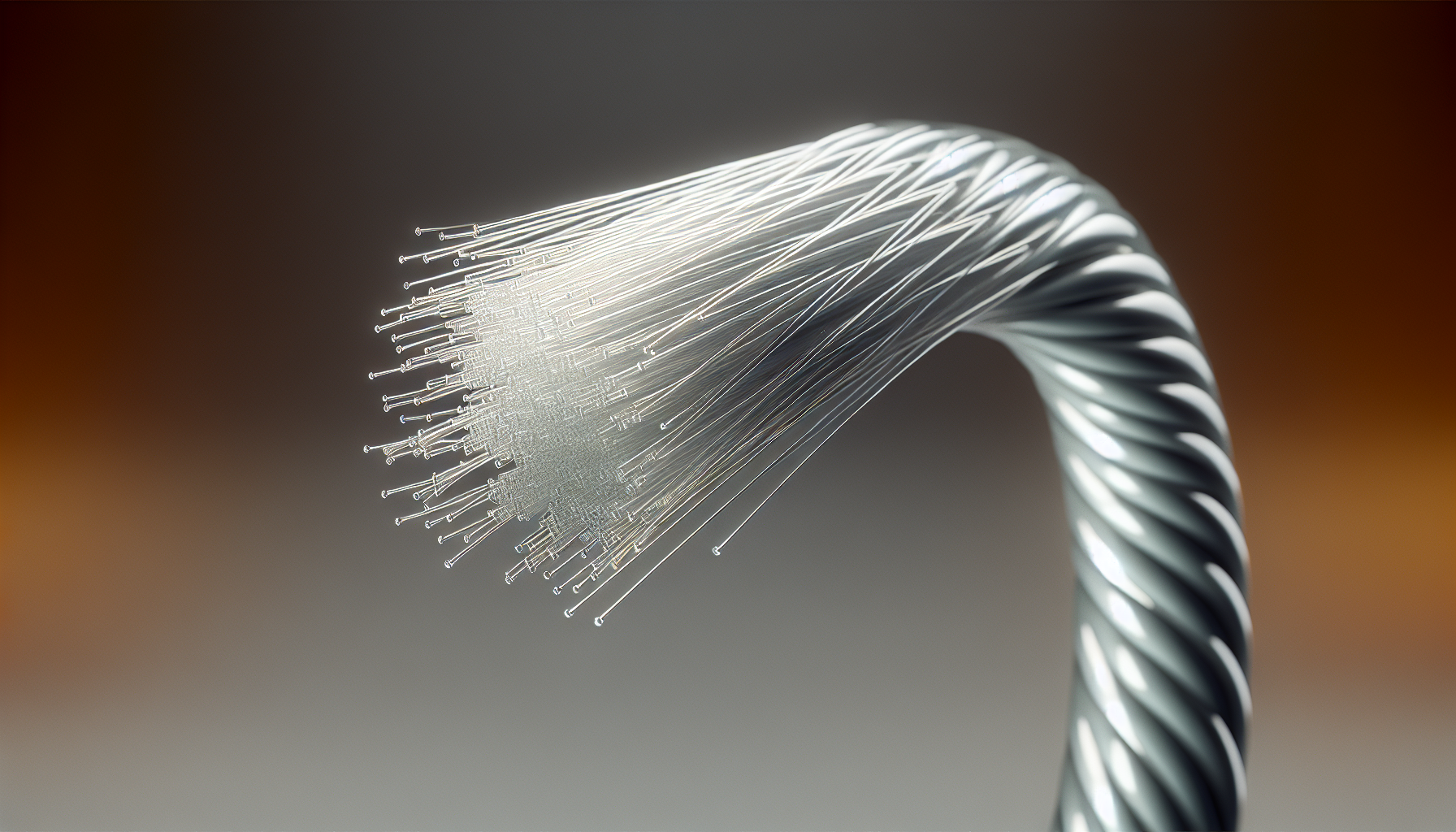

At its most basic, a fiber optic cable is a medium designed to transmit light signals over long distances with minimal loss. Each fiber cable consists of one or more optical fibers, each no thicker than a human hair. These fibers are made of glass or plastic, and their main function is to guide light from one end of the cable to the other. In this context, fiber cables refer to the same technology as fiber optic cables, utilizing optical fibers for efficient data transmission.

The choice of material for the fibers depends on the specific application. Glass fibers, predominantly made of silicon dioxide (SiO2), offer the advantages of compactness, lightweight properties, and resistance to electromagnetic interference, making them ideal for long-distance data transmission.

On the other hand, plastic fibers, manufactured from polymers, offer flexibility, ease of production, and cost-effectiveness, making them a suitable choice for short-distance applications.

The Glass Fiber Core

The heart of a fiber optic cable, where the transmission occurs, typically consists of silica, or silicon dioxide (SiO2), a material known for its high purity and tensile strength. The silica core allows for a straight and precise path for the light to travel, resulting in minimal signal loss even over long distances.

The combination of this feature and the glass fiber’s resistance to electromagnetic interference positions glass fiber cores as perfect for long-distance data transmission. They can support high bandwidth signal transmission with a lower loss per kilometer compared to other materials.

Plastic Optical Fibers: An Alternative

Another type of optical fiber used in fiber optic technology is Plastic optical fiber (POF), a variant made from polymer materials such as PMMA (acrylic), polystyrene, and polycarbonates. These fibers offer:

- Enhanced light transmission

- Greater flexibility and durability compared to their glass counterparts

- High flexibility and light weight, making them more adaptable for fiber optic communication, especially in unstable environments.

POFs, despite their advantages, have certain limitations. The most significant of these is their higher signal loss, which restricts their use to short-distance applications. This limitation is mainly due to their lower performance characteristics, which prevent them from maintaining signal quality over longer spans, unlike glass fibers.

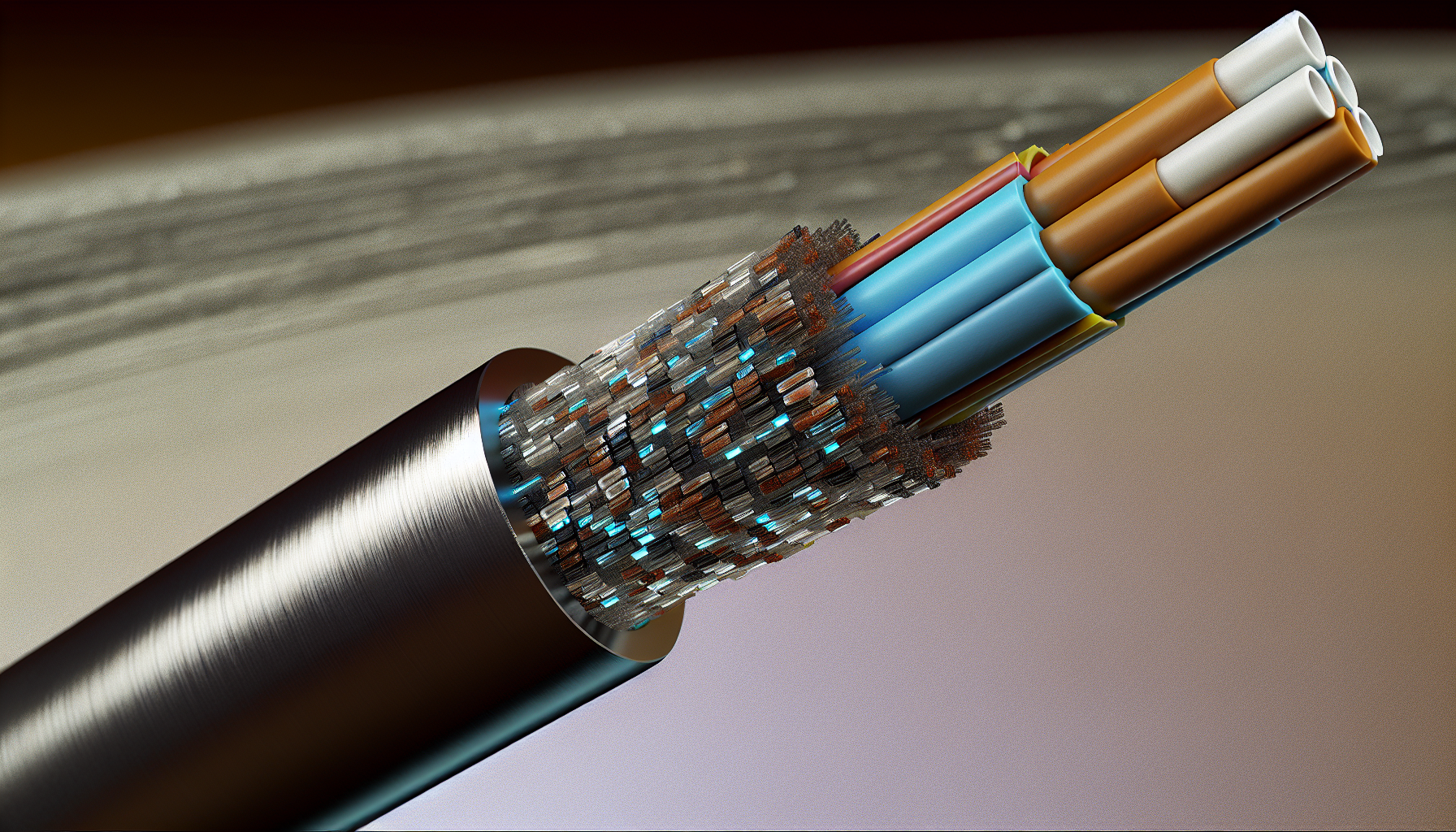

Cladding: The Protective Layer

Surrounding the core of the optical fiber is a layer known as the cladding. The cladding’s role is twofold. Firstly, it enhances the critical angle within the core fiber, ensuring that the light remains confined within the core and travels along the length of the fiber. Secondly, it acts as a barrier, preventing adjacent fibers from coming into contact with each other and protecting the cable from external interference.

Materials like PVC, polyurethane, and fluorinated polymer are often used for the cladding. A particular type of cladding material, fluoride-doped silica, decreases the refractive index, facilitating total internal reflection and thereby improving the cable’s radiation resistance and optical performance.

The Role of Buffer Tubes and Jacket Layers

Situated beyond the cladding is the buffer tube, a protective layer that shields the delicate fibers from external forces like crushing or bending, which could potentially damage them and cause signal loss. The buffer tubes are often made of acrylate plastic, which provides the necessary mechanical support and prevents moisture from affecting the cables, thus preserving signal integrity.

Typically made of PVC, the jacket is the cable’s outermost layer and provides additional protection against abrasion and moisture. In some cases, strength members such as Kevlar are integrated into the jacket to enhance its strength and improve the pull strength of the cables.

Fiber Types: Single Mode vs. Multimode

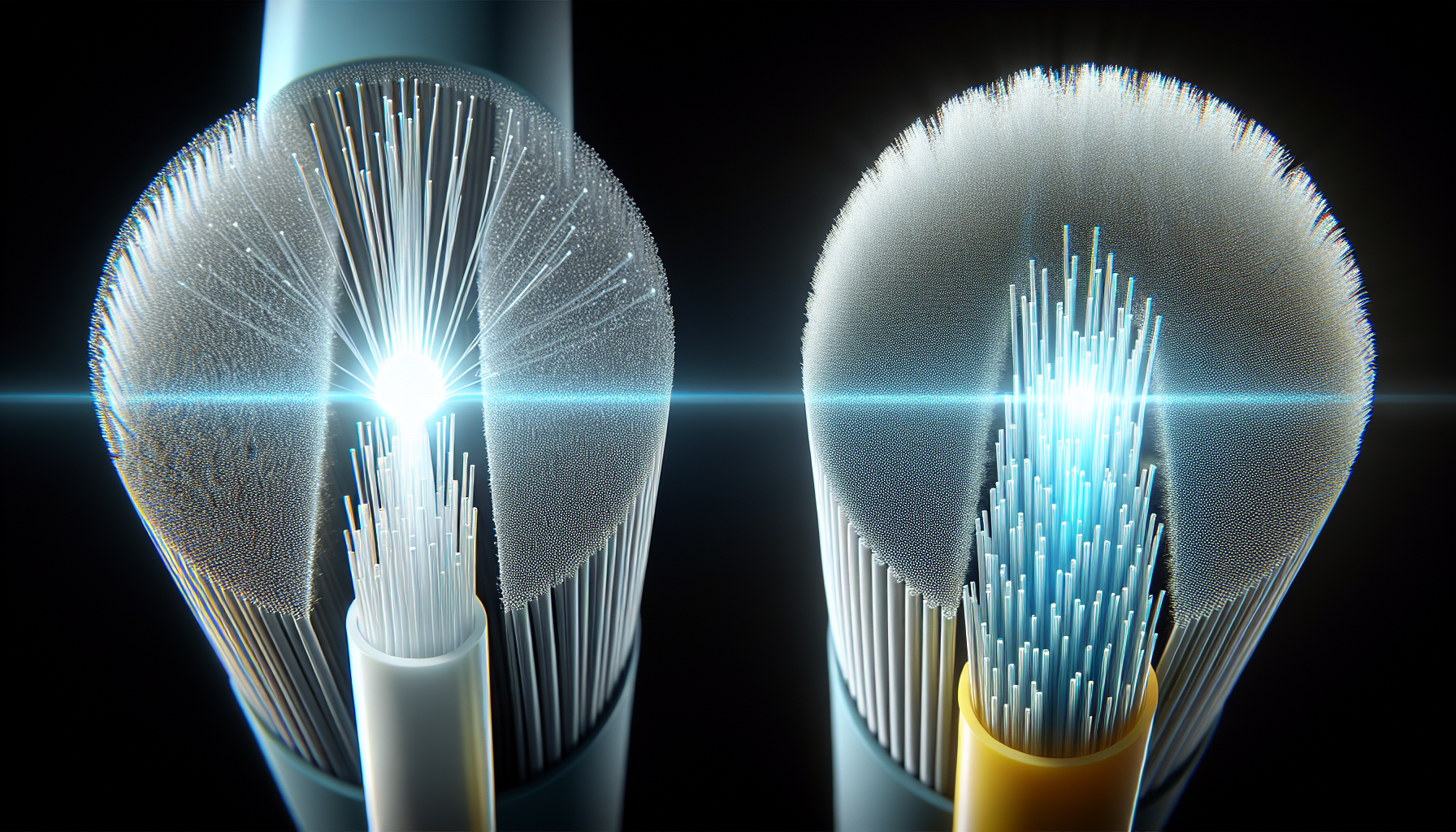

Not all cables are created equal, even though we’ve discussed the general structure of fiber optic cables. There are two main types of fiber optic cables: single-mode and multimode. Each type has specific use cases and characteristics. Each type has a specific design and is suited for particular applications and distances.

Single-mode fibers have a small diametral core and permit the propagation of only one mode of light. As a result, they are often used in long-distance transmission applications due to their low signal loss. On the other hand, multimode fibers, like OM1, feature a larger core diameter, allowing them to accommodate multiple data streams concurrently. This makes them ideal for establishing a company’s network backbone, managing multiple data streams simultaneously.

Single Mode Fiber: Precision for Long Distances

Single-mode fibers have a smaller core diameter, which promotes straight-line light transmission, reducing signal attenuation and allowing for longer transmission distances. As a result, single-mode fibers can transmit data over significantly longer distances compared to multimode fibers, with most electronics supporting up to 10 kilometers (6.2 Miles) on standard single-mode cables.

The high precision and reduced signal loss of single-mode fibers make them preferred for long-distance transmissions. In fact, with the help of advanced fiber optic splicing techniques, advanced cleaving techniques, and single-mode fiber optic rotary joints, signal losses can be minimized even further.

Multimode Fiber Optics: High Capacity Over Shorter Spans

On the flip side, multimode fibers have the following advantages:

- They have a larger core diameter, which allows them to accommodate multiple light modes, thereby enhancing the data capacity.

- However, this comes at the cost of increased signal loss over distances due to the overlapping light streams.

- To mitigate this, high-quality cables and splices should be used, joints should be minimized, and optical amplifiers should be incorporated along the route as required.

Despite this drawback, multimode fibers such as OM3 and OM4 can transmit data up to 300 meters and 550 meters respectively at speeds of 10 Gbps. This makes them an excellent choice for applications where high data capacity over shorter spans is required.

The Manufacturing Process of Optical Fibers

The process of manufacturing optical fibers is complex and intricate. It involves several steps:

- Precise control of temperature and speed to achieve the desired diameter and optical properties of the fibers.

- Application of a matrix material to bind the fibers together.

- Transformation of the preform into a hair-thin fiber through a process known as fiber drawing.

These steps ensure the production of high-quality optical fibers, capable of transmitting light pulses efficiently.

The buffering material is applied to safeguard the fibers from moisture, abrasion, and other external factors. Various methods, such as extrusion or powder coating, can be utilized for applying the buffering material based on the cable design and requirements.

Comparing Fiber Optic Cables to Traditional Copper Wires

Fiber optic cables have several advantages over traditional copper wire. The most obvious of these is their higher bandwidth. Fiber optic cables utilize light for data transmission, leading to significantly higher bandwidth compared to copper wires, which rely on electrical pulses. This variance in transmission method enables fiber optics to accommodate more data at accelerated rates.

Furthermore, fiber optic cables have several advantages over copper wires:

- They can transmit data at speeds of up to 10Gbps, while copper wires can only achieve speeds ranging from 25-300 Mbps.

- They exhibit significantly lower signal loss compared to copper wires.

- They have a longer signal distance capability, being able to carry signals up to 25 miles, whereas copper cables are limited to about 100 meters.

Despite these advantages, copper wires may still be preferred in situations where cost containment is crucial, as copper is typically more economical than fiber optics.

The Versatility of Fiber Optic Applications

It’s evident that fiber optic cables play a pivotal role across various industries. In computer networking, they enable rapid and effective communication between computer systems and are integral to the infrastructure of internet and cable TV, delivering high-speed broadband connectivity.

Moreover, they are utilized in undersea environments to connect continents and countries, facilitating long-distance data transmission with minimal loss. In the broadcasting industry, fiber optic cables establish high-bandwidth networks with minimal signal loss, which is essential for video over fiber solutions and overall network efficiency.

Whether it’s facilitating global communication or supporting high-definition television broadcasts, the versatility of fiber optic cables is truly remarkable.

Summary

From their humble beginnings in the 19th century to their prominence in today’s high-speed communication networks, fiber optic cables have come a long way. With their superior transmission capabilities, resistance to interference, and versatility, they’ve not only revolutionized the technology industry but also transformed the way we live, work, and communicate.

As we continue to push the boundaries of technology and demand faster, more efficient means of communication, the role of fiber optics will undoubtedly continue to grow. Whether it’s supporting the internet’s ever-increasing demand for speed and bandwidth or powering next-generation technologies like 5G, artificial intelligence, and the Internet of Things, fiber optics is set to continue playing a critical role in shaping our digital future.

Frequently Asked Questions

What is the main material used in Fibre optic cable?

Fiber optic cables are mainly made of high-quality glass or plastic materials like silica and plastic, designed to transmit light signals efficiently over long distances. These materials have impressive mechanical properties and can be engineered with reflecting and refracting properties essential for signal transmission.

What are the components of a fiber optic cable?

A fiber optic cable consists of the core, cladding, coating, strengthening fibers, and the cable jacket. These components work together to transmit data effectively.

Is fiber optic glass or plastic?

Fiber optics can be made from either optical-quality glass or plastic, both of which are used to transmit light energy over long distances. Glass and plastic are used to make the thin, transparent strands of optical fibers.

What are fiber optic cables not made of?

Fiber optic cables are not made of copper or any other metal. Instead, they are made up of extremely thin strands of flexible glass or plastic.

What’s the difference between single-mode and multimode fibers?

Single-mode fibers have a smaller core and are best for long-distance transmissions, while multimode fibers have a larger core and are suitable for short-distance, high-capacity applications.